INDUSTRIAL APPLICATIONS

Silicones & epoxides

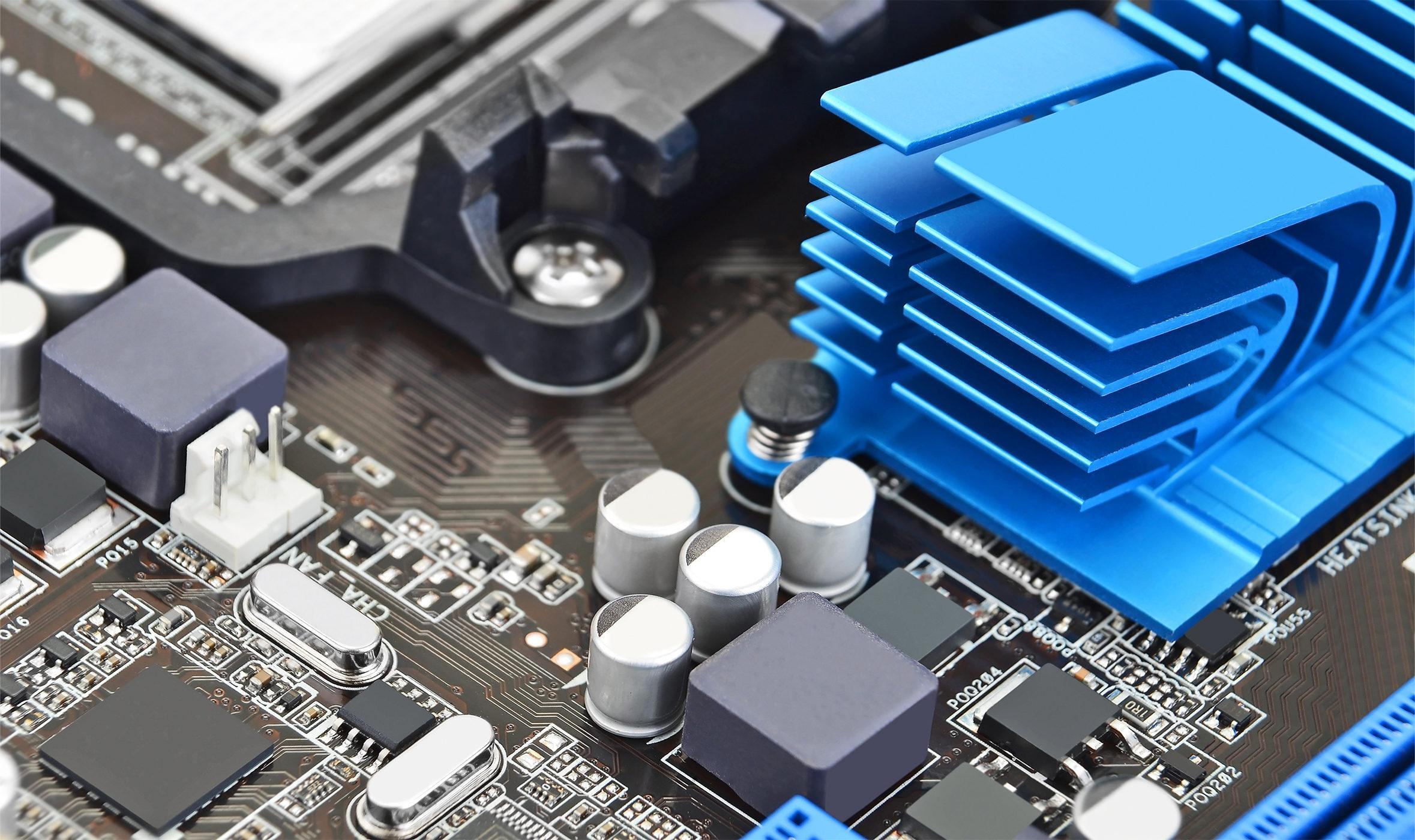

Diamonds bring everything except compromise to thermal interface and thermal management materials.

uDiamonds added to silicone and epoxide materials create polymer composites with significantly improved properties. The changes are due in part to the numerically high mechanical and thermal properties of diamond, and in part due to nanoscale effects obtained by dispersing small particles into the polymer material.

Typical Silicone-Nanodiamond applications:

- Increasing thermal conductivity of thermal interface materials in combination with other fillers, without affecting electrical isolation

- Increasing abrasion resistance

- Extending both the high and low temperature limits of operation

- Other properties still being explored

Nanodiamond may be added as a powder, using high shear and/ or ultrasonic dispersion, by pre-milling the nanodiamond together with other fillers, or via a compatible solvent borne dispersion.

Typical Epoxy-Nanodiamond applications:

- Increasing thermal conductivity of thermal interface materials in combination with other fillers, without affecting electrical isolation

- Increasing the strength of adhesives

- Increasing abrasion resistance of coatings and composite components

- Improving the impact resistance of composite panels

- Extending both the high and low temperature limits of operation

Carbodeon co-development model

We work closely with our customers to ensure the product achieves the targeted improvements. Nanodiamond may be added as a powder, using high shear and/ or ultrasonic dispersion, by pre-milling the nanodiamond together with other fillers, or via a compatible solvent borne dispersion.

We have direct experiences of polymer nanocomposite formulation in both silicones and epoxides so please do contact us to discuss your application.

PLA + uDiamond ®

Nanodiamond enhanced 3D filament